Introduction

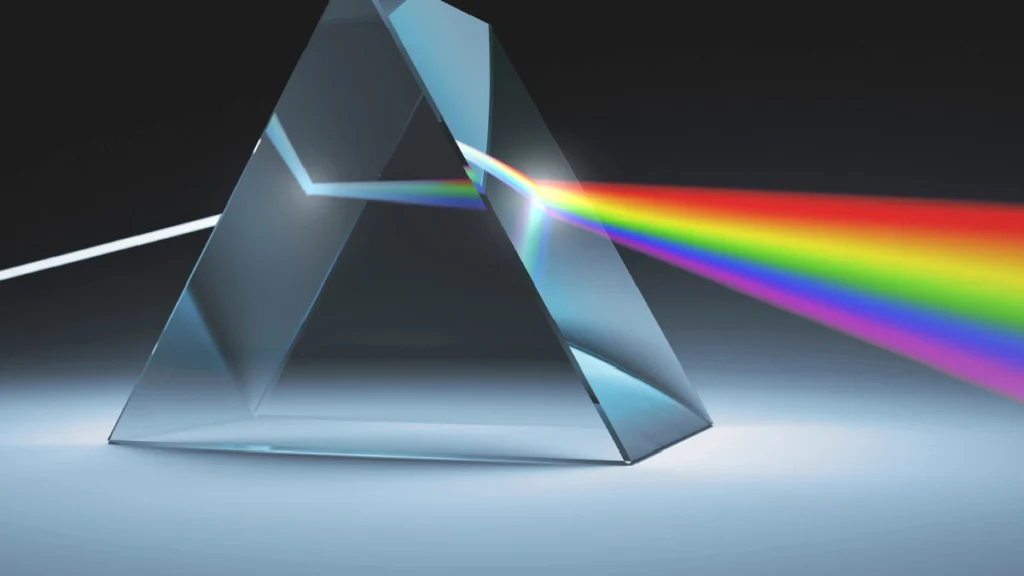

In today’s world of rapid innovation, one material is steadily rising to prominence: Prizmatem. A prism‑like composite that merges light-manipulating precision with robust durability, Prizmatem is reshaping optics, architecture, electronics, and beyond. This article explores its origins, technology, applications, and future potential—delivering an engaging, SEO-optimized view into why Prizmatem warrants your attention.

What Is Prizmatem?

Prizmatem is an advanced transparent composite that pairs silica-based micro‑prisms with a durable polymer matrix. Picture crystal-clear glass—but lighter, tougher, and able to channel light in vivid new ways. Its refractive index of around 1.60 rivals high-end optical glass, while maintaining over 90% transparency in the visible spectrum.

Through careful UV curing and nanofiller integration, Prizmatem achieves mechanical resilience previously unseen in materials of its kind. The result? A substance that bends, beams, and endures—all while challenging traditional materials like glass and acrylic.

How Prizmatem Works: Science Behind the Shine

- Prismatic architecture: Embedded micro‑prisms guide light through engineered paths, boosting brightness and clarity.

- Polymeric matrix: A UV-cured resin anchors prisms and enhances heat resistance.

- Nanofillers & coatings: These improve stress tolerance, scratch resistance, and UV stability Cordless.io.

Combined, these features create a lightweight composite capable of precision light manipulation, thermal endurance from –20 °C to +85 °C, and striking mechanical resilience.

Real-World Applications

Photography & Cinematography

Prizmatem lenses weigh up to 45% less than glass equivalents while retaining image sharpness. Their enhanced impact resistance is ideal for gear used in active environments.

Architecture & Lighting

Prismatic panels direct daylight into deeper interiors, reducing the need for artificial lighting and improving building energy efficiency.

Consumer Electronics & AR/VR

Slimmer optical components without glass bulk—think AR goggles, mobile lenses, and folding devices.

Medical Devices

Lightweight, sterilizable, and high-clarity materials streamline imaging instruments like endoscopes .

Automotive Displays

Shatter-resistant panels enhance the safety and longevity of head-up displays and light guides.

Greenhouse & Environmental Systems

Panels guide sunlight to shaded crops, boosting plant growth while aiding in climate control.

Strengths vs. Traditional Materials

| Feature | Prizmatem | Optical Glass | Acrylic |

|---|---|---|---|

| Refractive Index | ~1.60 | 1.50–1.90 | 1.49–1.50 |

| Weight | –45% vs. glass | Baseline | Baseline |

| Drop Resistance | High | Low | Moderate |

| Scratch Resistance | Strong (with coating) | Very High | Low |

| Thermal Range | –20 to +85 °C | –50 to +300 °C | –10 to +60 °C |

| UV Stability | Good (treated) | Excellent | Poor |

| Cost | Medium | High | Low |

This table reveals Prizmatem’s winning position—a near-glass clarity with superior resilience, reduced weight, and smart durability, all at optimized cost.

Sustainability & Eco Benefits

- Recyclable composite: Can be reprocessed into new forms or reused in other products.

- Low-energy UV curing: Less energy-intensive than many manufacturing methods.

- Lightweight transport: Reduces logistics emissions.

- Non-toxic and halogen-free: Safer for environments and humans.

Cost & Market Competitiveness

Prizmatem ranges $20–45/sq ft for panels and under $200 for high-quality lenses. Though pricier than acrylic, it’s notably cheaper than precision optical glass—making it a smart alternative for performance systems on a budget.

Challenges & Limitations

- UV curing sensitivity: Requires tightly controlled manufacturing environments.

- Still niche: Pilot programs predominate—mass adoption is evolving.

- Coating needs: Surfaces depend on additional treatments for scratch/UV defense.

- Regulatory milestones: Medical and architectural certifications are still progressing.

Emerging Innovations

- Active waveguides: For tunable optics in AR and adaptive glasses.

- Smart coatings: Self-cleaning, anti-fog, anti-scratch layers.

- Integrated conductors: Blending prizmated optics with transparent electronics.

- Recycling loops: Manufacturer take-back for circular lifecycle initiatives Cordless.io.

Case Studies

Camera Lenses: A boutique brand with Prizmatem optics launched models 25% lighter than their glass equivalents, without sacrificing optical clarity .

Greenhouse Design: Test projects show an 18% boost in plant growth via daylight redirecting panels .

Medical Endoscopy: Lightweight, sterilizable devices won praise for portability and clarity from clinical professionals .

Tips for Implementation

- Index matching: Match refractive index to your optical design.

- Shape advantage: Use molded pieces to reduce assembly complexity.

- Coating selection: Apply customized UV/scratch-resistant finishes.

- Start small: Pilot optics before scaling to architecture or industrial volumes.

- Compliance early: Begin regulatory pathways early in development.

FAQs

- What exactly is Prizmatem?

A high-performance composite of silica micro-prisms embedded in a UV-cured polymer matrix. It combines high optical clarity, robustness, and prismatic light control. - How does it compare to glass or acrylic?

It matches glass for clarity and outperforms acrylic in weight, impact resistance, thermal stability, and scratch resistance. - What industries currently use it?

Key sectors include photography, architecture, electronics, medical devices, automotive optics, and greenhouse systems. - Is Prizmatem eco-friendly?

Absolutely—it’s recyclable, non-toxic, low-energy produced, and lightweight for transport, aligning with sustainable practices. - Can it be customized?

Yes—designers can choose prism shapes, coatings, thicknesses, and refractive properties to meet specific application needs.

Conclusion

Prizmatem isn’t just another material; it’s a platform that fuses optics, durability, and sustainability. From lighter camera lenses to daylight-maximizing architecture, from AR-ready consumer tech to sterilizable medical tools, its transformative potential is indisputable. As industries demand smarter, lighter, greener solutions, Prizmatem stands poised to illuminate the future—literally.